Centralised Lubrication System Manufacturers

Centralised Lubrication System Manufacturers

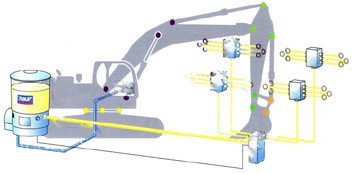

Automatic and Centralised Lubrication Systems provide precise amounts of lubricant to moving parts to minimise friction and wear. These systems are increasingly seen as mission-critical products aimed at improving equipment productivity, reliability, and energy efficiency.

We provide the following services for the above systems/manufacturers:

Programmed Maintenance

(our PMP Preventative Maintenance Program).

System Repairs & Maintenance

Installations**

Parts Supplied**

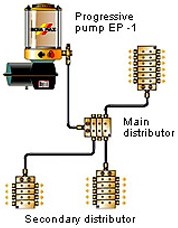

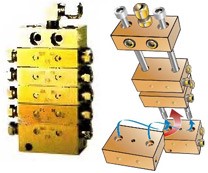

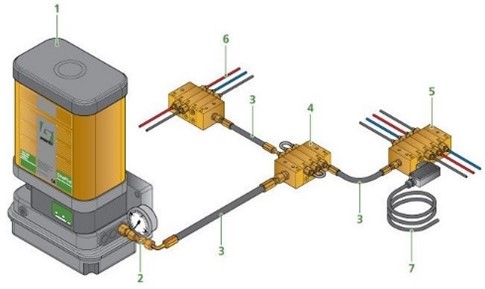

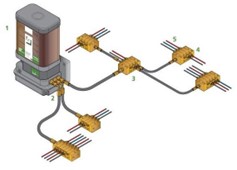

The Beka-Max lubrication pumps have various grease delivery methods according to the system type; for example, the EP 1 pump range, including the EP Tronic, works using a progressive grease delivery method, as does the Pico pump, which also can be a multi-line system.

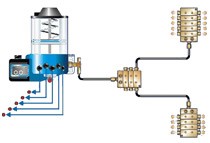

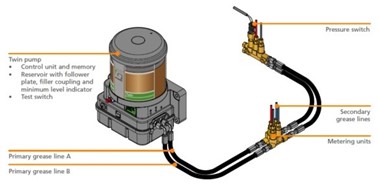

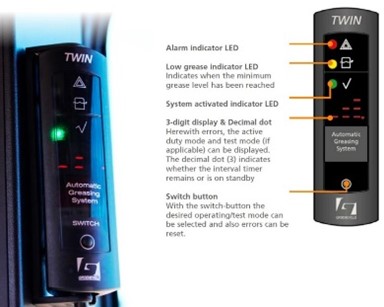

The Groeneveld lubrication pumps have various grease delivery methods according to the system type; for example, the Twin pumps use a dual/twin line grease delivery method, whereas the OnePlus, TriPlus and GPA pumps use a progressives grease delivery method.

Download Product Information

The SKF/Lincoln 203 lubrication pumps use a progressive grease delivery method.

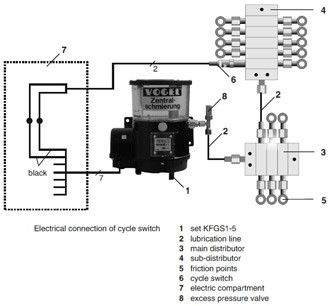

The SKF/Vogel lubrication pumps KFG / KFGS uses a progressive grease delivery method.

We also offer maintenance and service on other systems, I.E., Interlube HDI pumps and others